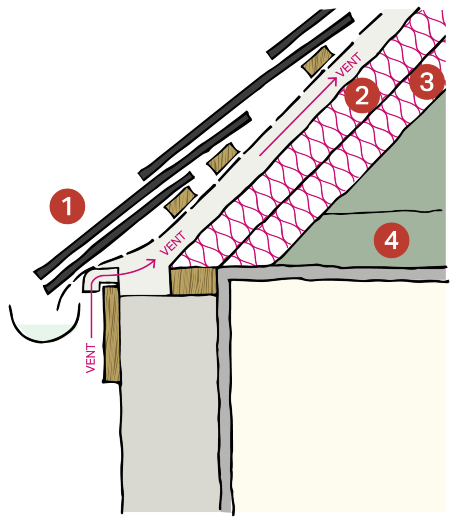

1. Some adjustments may be required to improve ventilation of the roof above the insulation. Vents, counter-battens, breathable underlays, and the like are basic measures which a builder or roofing contractor could fit.

2. Insulation is laid in alternate directions so as to eliminate heat loss through joints.

3. Typically rigid insulation boards are laid between and beneath the rafters to achieve the required level of insulation. Compressible insulation types can be held in place with a net or breathable building membrane. With insulation at rafter level, the roof can remain usable and tanks, pipes, and the like may not need separate insulation.

4. Retaining existing insulation at ceiling level will reduce the heat from the home spent warming the roof space.

This measure may require you to remove existing finishes. Also consider ecology by choosing bat-friendly insulation materials where possible.

The roof of a building is normally simply made from thin tile, slate, or lead coverings on a slender timber frame. With only this and a thin layer of plaster between the upper floor rooms and the outside, it is easy to see how heat can be readily lost through an unimproved roof.

For some later buildings, there is already insulation at rafter level, but most properties will likely have any insulation laid as a loose quilt between the ceiling joists. This arrangement is a good start, but the joists remain uninsulated, the insulation is often too thin, and in many cases poorly fitted, particularly around the eaves where the interior is closest to the outside. Top-up insulation is therefore often required.

Insulation at rafter level can be supplemented or newly retrofitted, and is typically set both between and beneath the rafters in alternate directions so as to reduce heat loss through the joints. Rigid insulation boards which are self-supporting can be used. Alternatively, soft insulation can be supported with a net or breathable building membrane.

Rafter level insulation products are normally higher performing to reduce the thickness required, but to achieve adequate performance it is recommended that loft insulation is the equivalent of c.300mm mineral wool or fibre quilt.

A ventilation path must be established above the insulation, to dissipate any moisture which could condense on the colder timbers or reduce the performance of the insulation. This will normally only involve basic adjustments of the building by a roofing contractor or builder.

Although a little more complex to fit than insulation at ceiling level, rafter level insulation allows the roof space to be used and reduces the need to upgrade loft access, water tanks, pipes, etc as the roof space is warm.

This technique will likely be required where the ceilings follow the line of the roof and there is no roof space available. Planning permission or permitted development rights would need to be used where the insulation is changing the roof height.

Each eaves detail needs careful thought once insulation is added. Often bespoke solutions have to be devised to achieve effective improvement.

Up to 35% of the heat loss from a home passes through the roof. This area is therefore very important to improve.

There are very many insulation systems and products available, with strong competition in price to ensure good value.

Rafter level insulation will normally recover its installation cost within 2-3 years.

Many systems can be retrofitted from below in less than a day, although some work may need to be undertaken by a contractor to ensure ventilation routes are achieved.

Listed Building Consent is not normally required for insulation of pitched roof spaces at floor level, as long as the insulation is not adhesive, avoids disturbance to historic fabric, and is easily reversible.

Listed Building Consent is not normally required for insulation of pitched roof spaces below the roof, as long as the insulation is not adhesive, avoids disturbance or harm to historic fabric and roof profiles, does not cover significant detailing and is easily reversible.

Listed Building Consent is not normally required for installation of pitched roof ventilation and should be discreet.

Listed Building Consent is required for insulation of flat roofs.

Permeable and traditional materials are preferable.

Insulation of pitched roof spaces at floor level is always preferable; other options should only be considered where this is not practical or possible (e.g. if the roof space is floored and forms part of the living space).

Ventilation in the roof space must be maintained. This may require the addition of roof vents – in such cases discreet conservation-grade roof vents should be selected (i.e. eaves vents or tile vents).

Quilt or rigid board insulation is preferable. Sprayed foams will not usually be acceptable, as they are not easily reversible should future repairs be required and are not permeable.

Be aware of disrupting decorative ceilings.

Below-roof insulation (pitched or flat roofs) can require temporary removal of surfaces – care should always be taken, and some insulation methods require less removal of fabric than others so research is required into the different options.

Care needs to be taken to preserve in situ historically significant internal surfaces such as plastered or decorated ceilings and skillings.

Roofs can be the least altered areas of historic buildings and care should be taken to maintain historic roof profiles, verge details, plaster surfaces and any other significant features or detailing.

Use of permeable materials, particularly sustainable natural materials such as sheep’s wool and wood fibre insulation, is encouraged to minimise the risk of condensation. There are many reputable suppliers of these materials which are produced and sold in the UK.

We support careful insulation of loft and roofs paces where there is no detrimental impact on the architecture or historic interest of the building, and advocate the use of permeable and sustainable traditional materials.

In the light of the Climate Emergency, we will generally permit and encourage alterations on listed buildings, with special regard to the the following:

- Preserving the building, its setting or any features of special architectural or historic interest which it possesses

- Preserving or enhancing the character of a conservation area

- Respecting the significance of any non-designated heritage asset

English Heritage Guidance on Insulating Roof at Ceiling level