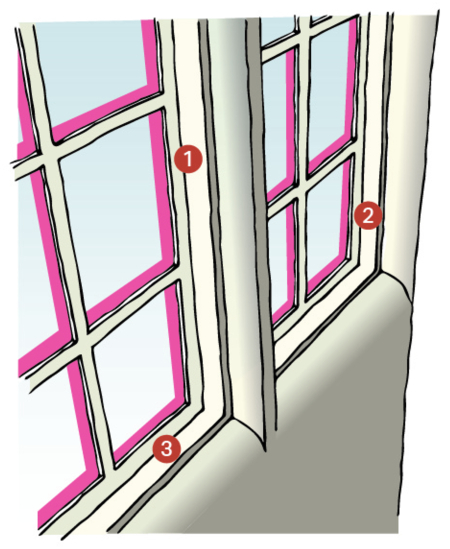

1. Proprietary compression and wiping seals, which can be discreetly fitted at the perimeter of the window, are also available.

2. A simple draught proofing technique is to apply around the window where the faces meet the frame, with a release tape applied to the frame. This achieves a good fit, with minimal impact on the building fabric and can be applied when re-decorating.

3. The gap between a metal window and its frame or surround can account for a significant amount of the heat loss. Improving the fit of the window by keeping it in good repair will help and draughtproofing will ensure the energy lost is kept to a minimum.

Most metal framed windows are single glazed with large plain glass panels, or in the case of earlier windows, with multiple small panes held in lead. Later windows often have a metal sub-frame, but early windows may be simply set in rebates against stone or timber surrounds.

In either case the closeness of fit between the opening parts of the window and their frame or surround will greatly affect the performance of the window by allowing draughts to enter and heat to leave the building.

In addition to placing the window in good repair, simple draughtproofing techniques can be used to improve the situation.

A simple technique such as release tape and a mastic bead can be part of the routine decoration of the window. Compressible and wiping seals are also commonly available which sit discretely at the junction between frame and window.

As much as 80% of the heat lost through a single glazed window can be through air-leakage or draughts and addressing this makes good sense.

As a conductive material, metal windows will always facilitate greater loss of heat compared to other non-conductive materials.

The simplest draughtproofing measures are DIY level installations and are therefore quite inexpensive. A mastic and tape decoration upgrade can be installed for less than £5.

Proprietary weather seals are available which vary in cost between simple self-adhesive profiles for less than £1 per metre, to those with profiled and replaceable seals for a little more. If DIY fitted, the cost will be modest and likely less than £20 per window.

Listed Building Consent is not normally required, unless the appearance of the room would be significantly affected.

Any mastic-type draught proofing should be as discreet as possible in colour, for example clear, or matching the surrounding colour as closely as possible.

Unobtrusive products should always be used.

Loss of historic fabric should be avoided.

Professional installation will be needed for products such as rebated edge seals.

Care should be taken to ensure the strength of the frame is not compromised.

We support careful draughtproofing of windows where there is no detrimental impact on the special architectural or historic interest of the building or historic fabric.

In the light of the Climate Emergency, we will generally permit and encourage alterations on listed buildings, with special regard to the the following:

- Preserving the building, its setting or any features of special architectural or historic interest which it possesses

- Preserving or enhancing the character of a conservation area

- Respecting the significance of any non-designated heritage asset

Draughtproofing Windows and Doors from Historic England

Draughtproofing Older Buildings also from Historic England